Product Description

| Thickness | Width | Length |

| 1-100mm | 10mm--3000mm | 1-50m |

|

Products |

Hardness ShoreA |

Density (g/cm3) |

Tensile strength (MPA) |

Elongation % |

Temperature range (ºC) |

| Hypalon rubber sheet | 60±5 | 1.4 | 6.0 | 300 | -30~+120 |

| Hypalon rubber sheet | 50±5 | 1.3 | 7.0 | 350 | -30~+120 |

Cloth insertion and nylon insertion are available.

Cloth impression finish is available.

Features

Hypalon rubber sheets offer a range of features that make them highly desirable for various industrial applications. Some of the key features of Hypalon rubber sheets include:

1. Chemical Resistance: Hypalon rubber sheets exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, oils, solvents, and oxidizing agents. This property makes them ideal for applications that involve contact with corrosive substances or environments.

2. Weather Resistance: Hypalon rubber sheets have exceptional resistance to outdoor environmental conditions, including ultraviolet (UV) radiation, ozone, rain, and temperature extremes. They can withstand prolonged exposure to these elements without significant degradation, making them suitable for outdoor applications.

3. Flexibility and Durability: Hypalon rubber sheets are known for their high flexibility and durability. They can endure mechanical stress, bending, and stretching without cracking or losing their sealing properties. They also have a low compression set, which means they can retain their original shape and elasticity even after prolonged compression.

4. Low-temperature Performance: Hypalon rubber sheets exhibit good performance at low temperatures, remaining flexible and maintaining their sealing properties even in cold environments. This makes them suitable for applications in refrigeration, cryogenics, and cold storage.

5. Electrical Insulation: Hypalon rubber sheets offer good electrical insulation properties. They can resist electrical current and prevent electrical leakage, making them suitable for applications that require electrical insulation.

6. Flame Resistance: Hypalon rubber sheets are inherently flame resistant and self-extinguishing. They have a high resistance to ignition and do not support combustion. This fire-resistant property makes them suitable for applications where fire safety is a concern.

7. Resistance to Abrasion and Wear: Hypalon rubber sheets exhibit good resistance to abrasion and wear, making them suitable for applications that involve contact with rough surfaces or materials.

8. High Tensile Strength: Hypalon rubber sheets have high tensile strength, which enables them to withstand mechanical stresses and loads. This property makes them durable and long-lasting in demanding industrial environments.

9. Good Adhesion: Hypalon rubber sheets have good adhesion properties, allowing them to bond well with various substrates and materials. This enhances their versatility and makes them suitable for applications that require strong adhesion.

10. Ease of Processing: Hypalon rubber sheets can be easily processed and fabricated using common methods such as cutting, molding, extrusion, and bonding. This allows for customization and ease of integration into specific applications.

It is important to note that the specific features and characteristics of Hypalon rubber sheets can vary depending on the grade and formulation of the material. Consulting with manufacturers or suppliers can provide more detailed information on the specific features of Hypalon rubber sheets for a particular application.

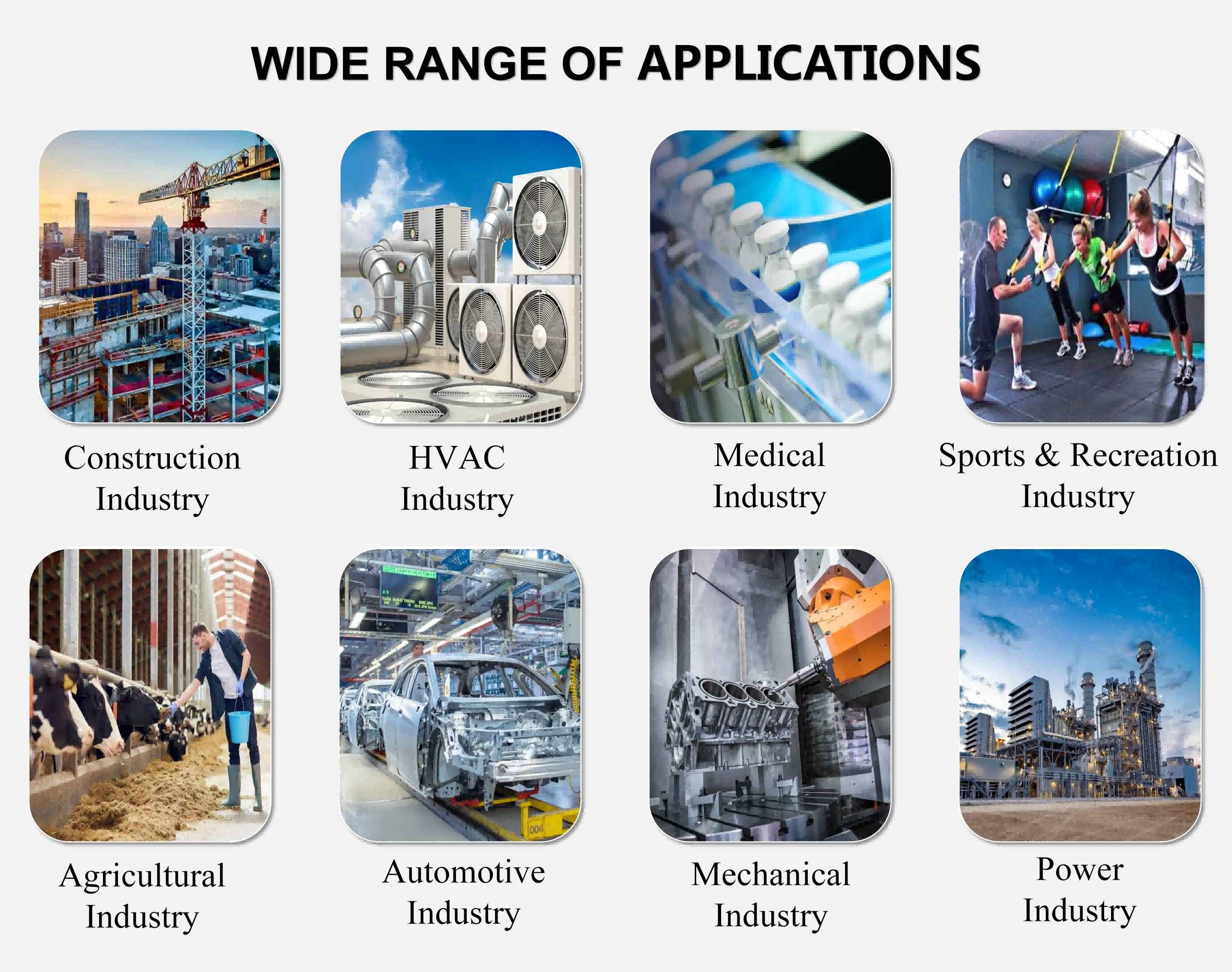

Applications

Hypalon, also known as chlorosulfonated polyethylene (CSPE), is widely used in various applications due to its excellent chemical resistance, weather resistance, durability, and other desirable properties. Here are some common applications of Hypalon:

1. Industrial Linings: Hypalon is widely used as a lining material for tanks, pipes, and other equipment in industries such as mining, chemical processing, and wastewater treatment. Its resistance to chemicals and abrasion makes it suitable for protecting equipment from corrosive substances and extending their lifespan.

2. Roofing Membranes: Hypalon roofing membranes are used in commercial and industrial buildings to provide a durable and weather-resistant roofing solution. Hypalon's excellent resistance to UV radiation, ozone, and extreme temperatures make it ideal for withstanding harsh outdoor conditions.

3. Inflatable Boats and Life Rafts: Hypalon-coated fabrics are extensively used for manufacturing inflatable boats, life rafts, and other marine applications. Hypalon's resistance to UV radiation, abrasion, and chemicals ensures the longevity and performance of these watercraft.

4. Chemical Hoses and Gaskets: Hypalon is employed to manufacture chemical-resistant hoses and gaskets, which are used to transport and seal various chemicals. Its resistance to a wide range of chemicals ensures safe and efficient handling of corrosive substances in industries such as chemical manufacturing and petrochemicals.

5. Conveyor Belts and Rollers: Hypalon is utilized in the production of conveyor belts and rollers, providing excellent resistance to wear, abrasion, and chemicals. This makes Hypalon suitable for heavy-duty material handling applications in industries like mining, recycling, and manufacturing.

6. Expansion Joints: Hypalon is used in the production of expansion joints, which are designed to accommodate thermal expansion and contraction in various structures like bridges, buildings, and pipelines. Hypalon's flexibility, durability, and resistance to weather and chemicals ensure the long-term performance of these joints.

7. Electrical Insulation: Hypalon is employed as an electrical insulation material due to its good dielectric strength and resistance to high temperatures. It is used in applications such as cables, wires, connectors, and electrical tape.

8. Automotive Applications: Hypalon finds use in automotive applications such as seals, gaskets, and hoses, where resistance to oils, fuels, and other automotive fluids is required.

9. Sports and Recreation Equipment: Due to its durability and resistance to UV radiation, Hypalon is used in the manufacturing of various sports and recreational equipment, including protective covers, inflatable structures, and water-resistant fabrics.

10. Other Applications: Hypalon finds use in a range of other applications, including chemical storage liners, pond liners, seals, diaphragms, and personal protective equipment.

These are just a few examples of the many applications of Hypalon. Its versatility, durability, and chemical resistance make it a popular choice in diverse industries.

Why Us

Packaging & Transportation

Kingwork New Materials Co.,Ltd

Kingwork New Materials Co.,Ltd