Product Description

| Thickness | Width | Length |

| 1-100mm | 10mm--3000mm | 1-50m |

|

Products |

Hardness ShoreA |

Density (g/cm3) |

Tensile strength (MPA) |

Elongation % |

Temperature range (ºC) |

| EPDM RUBBER SHEET | 65±5 | 1.4 | 5.0 | 300 | -30~+120 |

| HIGH GRADE EPDM | 70±5 | 1.3 | ≥10 | 400 | -30~+130 |

Specifications can be customized.

Cloth insertion and nylon insertion are available.

Cloth impression finish is available.

Features

-

Weather resistance: EPDM rubber sheets are highly resistant to weathering, ozone, and UV radiation. They can withstand exposure to sunlight, rain, snow, and extreme temperatures without deteriorating or cracking. This makes them ideal for outdoor applications and roofing.

-

Chemical resistance: EPDM rubber sheets have excellent resistance to a wide range of chemicals, including acids, alkalis, and polar solvents. They can withstand exposure to oils, fuels, and many industrial chemicals without swelling or degradation.

-

Temperature resistance: EPDM rubber sheets can withstand a wide range of temperatures, from -40°C to +120°C (-40°F to +248°F) or even higher with special formulations. They maintain their flexibility and elasticity even in extreme temperatures, making them suitable for both hot and cold applications.

-

Electrical insulation: EPDM rubber sheets have good electrical insulation properties. They can resist the flow of electric current, making them suitable for electrical applications such as cable insulation, electrical connectors, and gaskets for electrical enclosures.

-

Excellent physical properties: EPDM rubber sheets have good tensile strength, tear resistance, and elongation properties. They are flexible and can be easily molded or fabricated into various shapes and sizes. EPDM rubber sheets also have good compression set resistance, meaning they can maintain their shape and elasticity even after being compressed.

-

Low permeability: EPDM rubber sheets have low permeability to gases and liquids, making them suitable for sealing applications. They provide an effective barrier against moisture, air, and other environmental elements, preventing leaks and ingress.

-

Longevity and durability: EPDM rubber sheets are known for their longevity and durability. They have a long service life and can withstand frequent use and exposure to harsh conditions without significant degradation.

Overall, EPDM rubber sheets offer a combination of excellent weather resistance, chemical resistance, temperature resistance, electrical insulation, and physical properties, making them a versatile choice for various industrial applications.

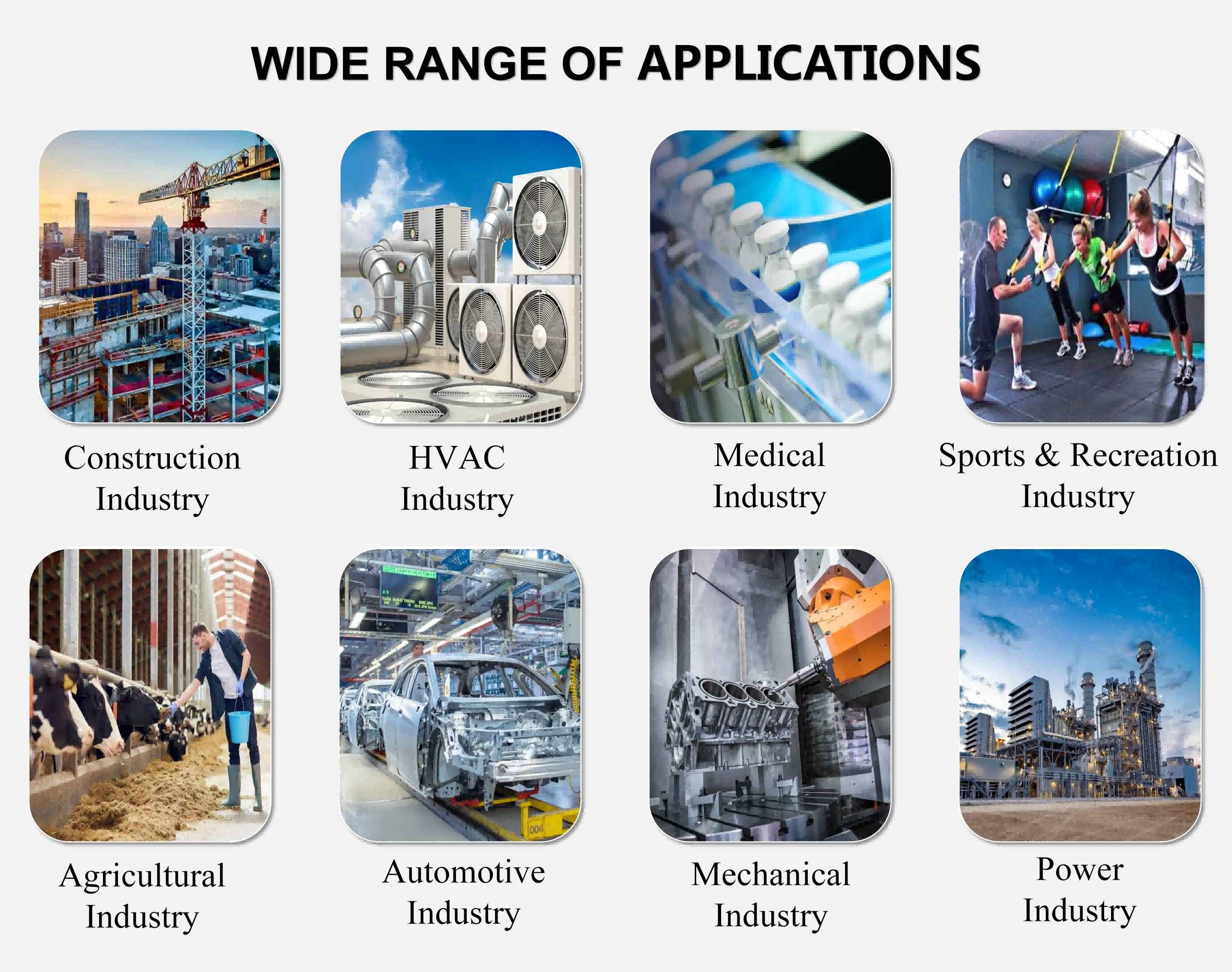

Applications

-

Roofing: EPDM rubber sheets are widely used in roofing applications due to their excellent resistance to weathering, UV radiation, and extreme temperatures. They provide a durable and long-lasting solution for flat roofs, green roofs, and other roofing systems.

-

Automotive industry: EPDM rubber sheets are used in various automotive applications such as weatherstripping, window seals, door seals, and gaskets. They provide excellent resistance to weathering, ozone, and chemicals, making them suitable for outdoor and harsh environments.

-

Electrical insulation: EPDM rubber sheets are used for electrical insulation purposes due to their excellent dielectric properties and resistance to electrical current flow. They are used in applications such as cable insulation, electrical connectors, and insulating gaskets.

-

Sealing and gaskets: EPDM rubber sheets are widely used for sealing and gasketing applications due to their excellent resistance to water, steam, chemicals, and gases. They are used in industries such as HVAC, plumbing, automotive, and construction.

-

Industrial applications: EPDM rubber sheets find applications in various industrial sectors such as food processing, pharmaceuticals, oil and gas, and chemical processing. They are used for applications such as conveyor belts, vibration dampening, expansion joints, and tank linings.

-

Marine applications: EPDM rubber sheets are used in the marine industry for applications such as boat fenders, hatch seals, and gaskets. They provide excellent resistance to water, saltwater, and UV radiation.

-

Sports and leisure: EPDM rubber sheets are used in sports and leisure applications such as playground surfaces, running tracks, and sports field infill. They provide a safe and durable surface with excellent shock absorption and weather resistance.

Overall, the application of EPDM rubber sheets is vast and diverse, thanks to their excellent properties such as weather resistance, UV resistance, chemical resistance, and electrical insulation.

Why Us

Packaging & Transportation

Kingwork New Materials Co.,Ltd

Kingwork New Materials Co.,Ltd